Planetary gear

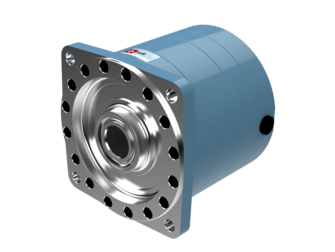

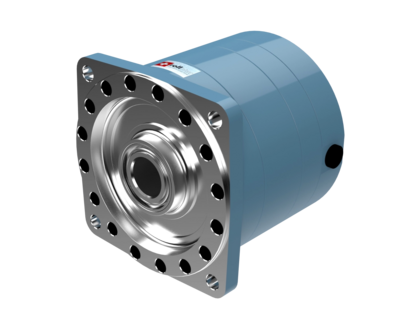

Rollstar planetary gears are space-saving drives for high torques with low weight and minimum dimensions.

Rollstar planetary gears are available up to a maximum output torque of 6.5 million Nm. They have a modular design and practically every size is available with different reductions. This results in an almost infinite number of possible combinations in order to be able to achieve any desired reduction.

How a planetary gear works

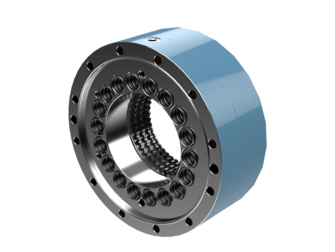

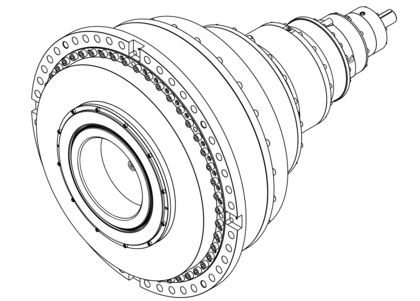

In its simplest form, a planetary gear consists of three coaxial shafts that interact with each other via specially arranged gears.

Planetary gears are epicyclic gear systems whose shafts and axles revolve on circular paths in the frame, the so-called planetary carrier. The wheels turning on the revolving axles orbit a central wheel, much like planets orbit the sun. This results in the component designations such as sun gear shaft, planet gear and planet carrier.

The sun gear is connected to the innermost shaft: it is externally toothed and usually meshes with three to six planet gears that circle it. These planets are mounted in the planet carrier, the one with the second shaft, so as to be freely rotatable about their own axis.

The outermost component is the internally toothed ring gear, which also meshes with the planet gears. According to this principle, the input speed of the respective planetary stage is decreased while the torque increases.

High torque density

The advantage of a planetary gear is that the greatest possible torques can be transmitted in a compact design. This is referred to as torque density. With the planetary gearboxes from Rollstar, torques of up to 6,500,000 Newton meters can be transmitted very space-savingly.

Planetary gear shiftable

Shiftable planetary gearboxes are available both in combination with our hydraulic motors and only as gearboxes.

These planetary gears, which can be shifted exclusively at a standstill, are available in a two-stage or three-stage design. The shifting takes place via a hydraulic or manual shifting link. We offer standard manual transmissions up to a maximum torque of approx. 7,500 Nm. Due to their extremely compact design, they are mainly used for power rotary heads in earth drilling equipment.

Rollstar is also continuously developing shiftable solutions for larger planetary gears, currently up to 300,000 Nm. We are happy to meet your special requirements.

Attachment to hydraulic or electric motors

Our planetary gearboxes are ideal for mounting on the Rollstar hydraulic motors.

Of course, it is also possible to attach a motor of your choice, whether hydraulic or electric. In addition, a large selection of output variants is available. Do not hesitate to let us know your special request.

3D models for construction

We make the CAD data of our products available on the TraceParts platform.

Engineers and planners can thus integrate our motors, gears and brakes directly into their design. We are happy to support you with questions about the technical solutions.

Do you have any questions or a special request?

We will be happy to assist you.